18 Years Factory Lab Atomization Equipment - Vacuum Gas Atomization Equipment – ShuangLing

18 Years Factory Lab Atomization Equipment - Vacuum Gas Atomization Equipment – ShuangLing Detail:

1. Equipment application

This equipment is mainly used for metal or metal alloy melting in vacuum and then atomization in atomization chamber under the gas protection environment to produce metal powder or metal granule.

The vacuum type gas atomization equipment is used for production the metal powder with high control requirement of oxygen content increment, at the same time, it own all powder production functions of antivacuum gas atomization equipments.

2. Equipment capacity

30KG-1000KG/batch for choose.

3. Equipment cover area

Length*Width*Height: 6M*7M*7-12M.

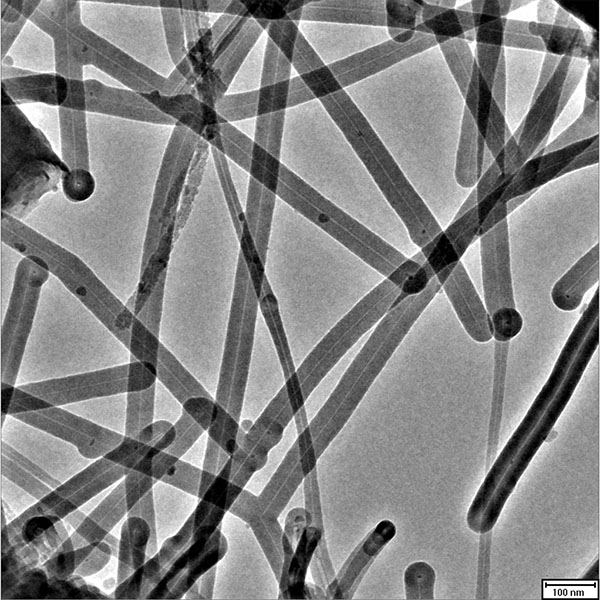

Product detail pictures:

Related Product Guide:

3D Printing Industry News Sliced: Stratasys, Markforged, XYZprinting and more | Ultrasonic Emulsifying Equipment

How Differences in Powder Density Impact 3D Printing Quality | Electric Melting Furnace

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for 18 Years Factory Lab Atomization Equipment - Vacuum Gas Atomization Equipment – ShuangLing , The product will supply to all over the world, such as: Kenya , Estonia , Russia , They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a must for yourself personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We have been confident that we will have a vibrant prospect and to be distributed all over the world in the years to come.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.

Write your message here and send it to us