2017 Latest DesignPressure Atomizing Direr - Rotary Metal Powder High Temperature Sintering Furnace – ShuangLing

2017 Latest DesignPressure Atomizing Direr - Rotary Metal Powder High Temperature Sintering Furnace – ShuangLing Detail:

This equipment is researched and made by our company and General Research Institute for Nonferrous Metals together, it can produce continuously, material can be rotation sintering in high temperature crucible under atmosphere protection environment, and it can carry out fast cold treatment for the material.

1. Application

It is mainly used for several kinds of rare earth, metal powder, nonmetal powder materials sintering production and experiment in high temperature or super high temperature. The materials rotate and sinter in high temperature crucible, the powder can be uniformity and high temperature sintering. The finished products can fall into finished products chamber automatically, and take fast cold treatment for materials.

2. Main functions

The equipment can rotary heat and sinter powder materials in vacuum or atmosphere under 2200℃.

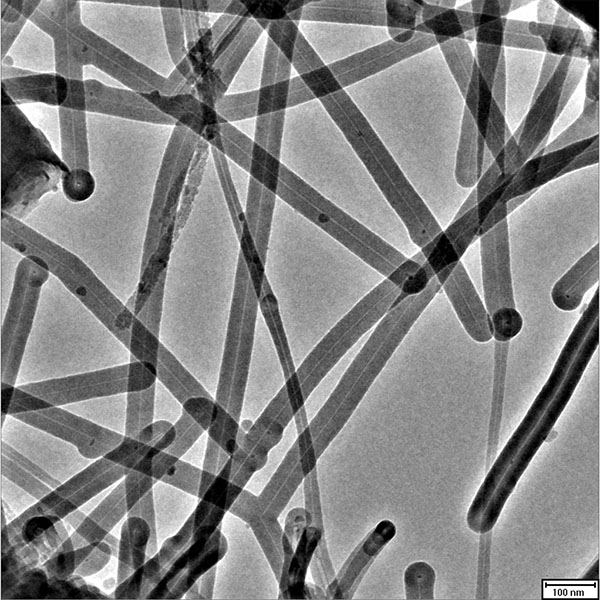

Product detail pictures:

Related Product Guide:

A Tour of The Modernist Cuisine Kitchen Laboratory | Champagne Gold Atomiser

AMG Advanced Metallurgical Group N.V. (AMVMF) CEO Heinz Schimmelbusch on Q1 2019 Results | Vacuum Induction Melting Furnace

We know that we only thrive if we could guarantee our combined price tag competiveness and quality advantageous at the same time for 2017 Latest DesignPressure Atomizing Direr - Rotary Metal Powder High Temperature Sintering Furnace – ShuangLing , The product will supply to all over the world, such as: Costa rica , Serbia , Dominica , Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we give our clients with high quality products and solutions and excellent service. Be sure to feel free to contact us for further information.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.