Factory Free sample Pipe Expander - CIGS &High Purity Metal Powder Gas Atomization Equipment – ShuangLing

Factory Free sample Pipe Expander - CIGS &High Purity Metal Powder Gas Atomization Equipment – ShuangLing Detail:

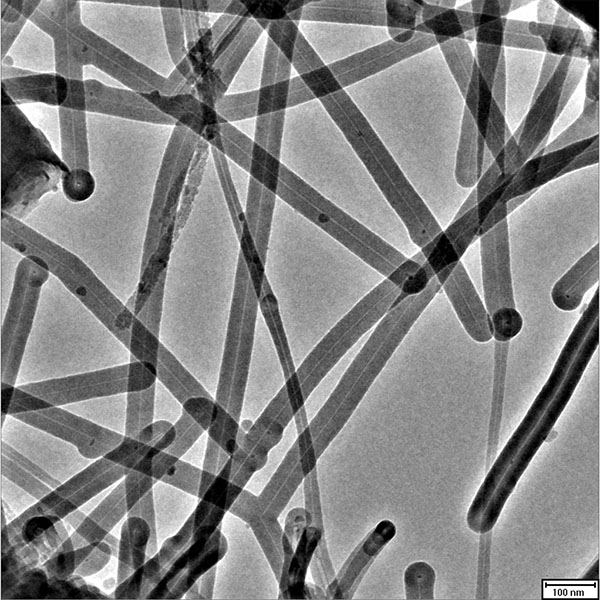

This equipment adopts high pressure gas atomization to make high purity metal powder, the powder has many advantages like low oxygen content, small particle size, narrow particle size distribution, better spherical shape, high apparent density, low loss and so on. The system is quite special at production the high purity metal powder, it can atomization the metal powder with purity larger than 99.9999%.

This equipment is mainly used for research and production high purity metal powder. The equipment is espeically used for high purity copper indium gallium selenide(CIGS) powder.

Equipment capacity: 30-250KG/batch or according to customer’s requirements.

Product detail pictures:

Related Product Guide:

Industrial Furnaces and Ovens Markets 2016-2024 | 3d Printing Powder Atomizing Equipment

BioSolar Signs a Joint Development Agreement with Ferroglobe, the Global Leader in the Supply of Silicon Material Other OTC:BSRC | Champagne Gold Atomiser

carry on to further improve, to guarantee merchandise high-quality in line with market and buyer standard necessities. Our organization has a top quality assurance procedure have already been established for Factory Free sample Pipe Expander - CIGS &High Purity Metal Powder Gas Atomization Equipment – ShuangLing , The product will supply to all over the world, such as: UAE , Cannes , Cologne , Since its foundation , the company keeps living up to the belief of "honest selling , best quality , people-orientation and benefits to customers. " We're doing everything to supply our customers with best services and best solutions . We promise that we are going to be responsible all the way to the end once our services begin.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

Write your message here and send it to us