Good Quality Car Wash Steamer - 3D Printing Metal Powder Atomization Equipment – ShuangLing

Good Quality Car Wash Steamer - 3D Printing Metal Powder Atomization Equipment – ShuangLing Detail:

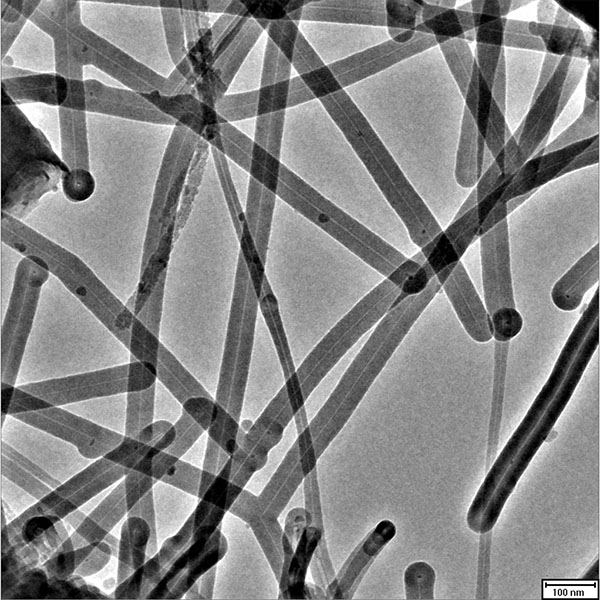

This equipment adopts high pressure gas atomization to make metal powder, the powder has many advantages like low oxygen content, small particle size, narrow particle size distribution, better spherical shape, high apparent density.

This equipment is suitable for all universities, institutes and companies to make researches or production 3D printing metal powder.

This equipment is suitable for production various types of powder such as a variety of stainless steel powder,high speed steel metal powdr, Co-Cr alloy powder, steel alloy powder, titanium alloy powder, copper powder, welding powder and so on.

Equipment capacity: 30-1000KG/batch

Equipment power: 120-1000KW

Equipment size L*W*H: 6.0m*6.0m*(6.0-10.0) m

3D Printing Metal Powder Atomization Equipment have obtained national invention patent and Hunan Province first set important technical equipment award.

Product detail pictures:

Related Product Guide:

How North Korea Was Armed – Analysis | Vacuum Induction Melting Furnace

Tata Steel to build £15mn furnace at UK plant | Champagne Gold Atomiser

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction for Good Quality Car Wash Steamer - 3D Printing Metal Powder Atomization Equipment – ShuangLing , The product will supply to all over the world, such as: Bogota , Ecuador , Latvia , For many years, we now have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.