OEM Factory for Automatic Pipe Bending Machine - CIGS &High Purity Metal Powder Gas Atomization Equipment – ShuangLing

OEM Factory for Automatic Pipe Bending Machine - CIGS &High Purity Metal Powder Gas Atomization Equipment – ShuangLing Detail:

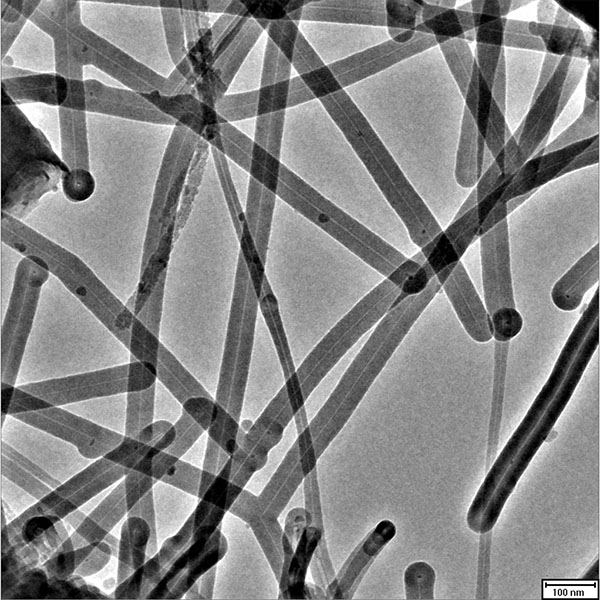

This equipment adopts high pressure gas atomization to make high purity metal powder, the powder has many advantages like low oxygen content, small particle size, narrow particle size distribution, better spherical shape, high apparent density, low loss and so on. The system is quite special at production the high purity metal powder, it can atomization the metal powder with purity larger than 99.9999%.

This equipment is mainly used for research and production high purity metal powder. The equipment is espeically used for high purity copper indium gallium selenide(CIGS) powder.

Equipment capacity: 30-250KG/batch or according to customer’s requirements.

Product detail pictures:

Related Product Guide:

Mulliner Makes Bentley Flying Spur Even More Special | Vacuum Induction Melting Furnace

PyroGenesis reports FY2018 earnings, anticipates “imminent contracts” of $32 million | 3d Printing Powder Atomizing Equipment

As for competitive charges, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we have been the lowest around for OEM Factory for Automatic Pipe Bending Machine - CIGS &High Purity Metal Powder Gas Atomization Equipment – ShuangLing , The product will supply to all over the world, such as: Sudan , Croatia , Brisbane , We're your reliable partner in the international markets of our products and solutions. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade solutions in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We're willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!

Write your message here and send it to us