OEM Factory for Gas Atomization System - Medium Frequency Induction Pipe Expanding Machine – ShuangLing

OEM Factory for Gas Atomization System - Medium Frequency Induction Pipe Expanding Machine – ShuangLing Detail:

Medium frequency induction pipe expanding machine

1. Equipment application

This equipment is mainly used to make straight pipe to cone pipe by medium frequency induction heating.

2. Specifications

2.1. Main technical parameters

The processing procedure is as follows: Adjust each part (heating temperature, oil cylinder propulsion speed) to the appropriate data, a key activation. Each part start work, medium frequency power supply start, then heat the core rod to 800 ℃ begin to insulation. Steel pipe roller and feeding auxiliary oil cylinder will push and fix the steel pipe to process in processing position. The sensors and core rod move to the steel pipe by oil cylinder. Auxiliary oil cylinder and core rod will down after fixing the steel pipe, from the pipe expanding start to finish.

The feeding Carmen automatically move and fix steel pipe large elbow, the sensors and mandrel go back to proper distance, the feeding Carmen leave the steel pipe automatically the core rod and sensors return back to the origin place. The supporting roller rise and push the finished steel pipe, the finished steel pipe run automatically into finished products area. The pipe expanding work is finished.

2.2. Accessories

Medium frequency power supply, automatic load system, unload machine, automatic positioning system, push system, sensors, hydraulic system, automatic control system and so on.

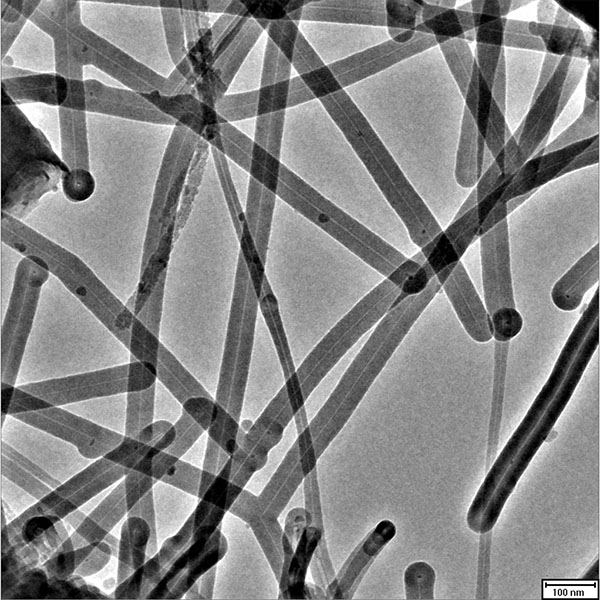

Product detail pictures:

Related Product Guide:

Desktop Metal ships and installs first ever Production System | Champagne Gold Atomiser

GE Additive to deliver 2 Concept Laser machines to Eaton Aerospace & moves gas atomizer equipment from Avio Aero to AP&C | Vacuum Induction Melting Furnace

To be the stage of realizing dreams of our employees! To build a happier, far more united and far more specialist team! To reach a mutual profit of our customers, suppliers, the society and ourselves for OEM Factory for Gas Atomization System - Medium Frequency Induction Pipe Expanding Machine – ShuangLing , The product will supply to all over the world, such as: Belarus , Chile , America , Although continuous opportunity, we have now now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.